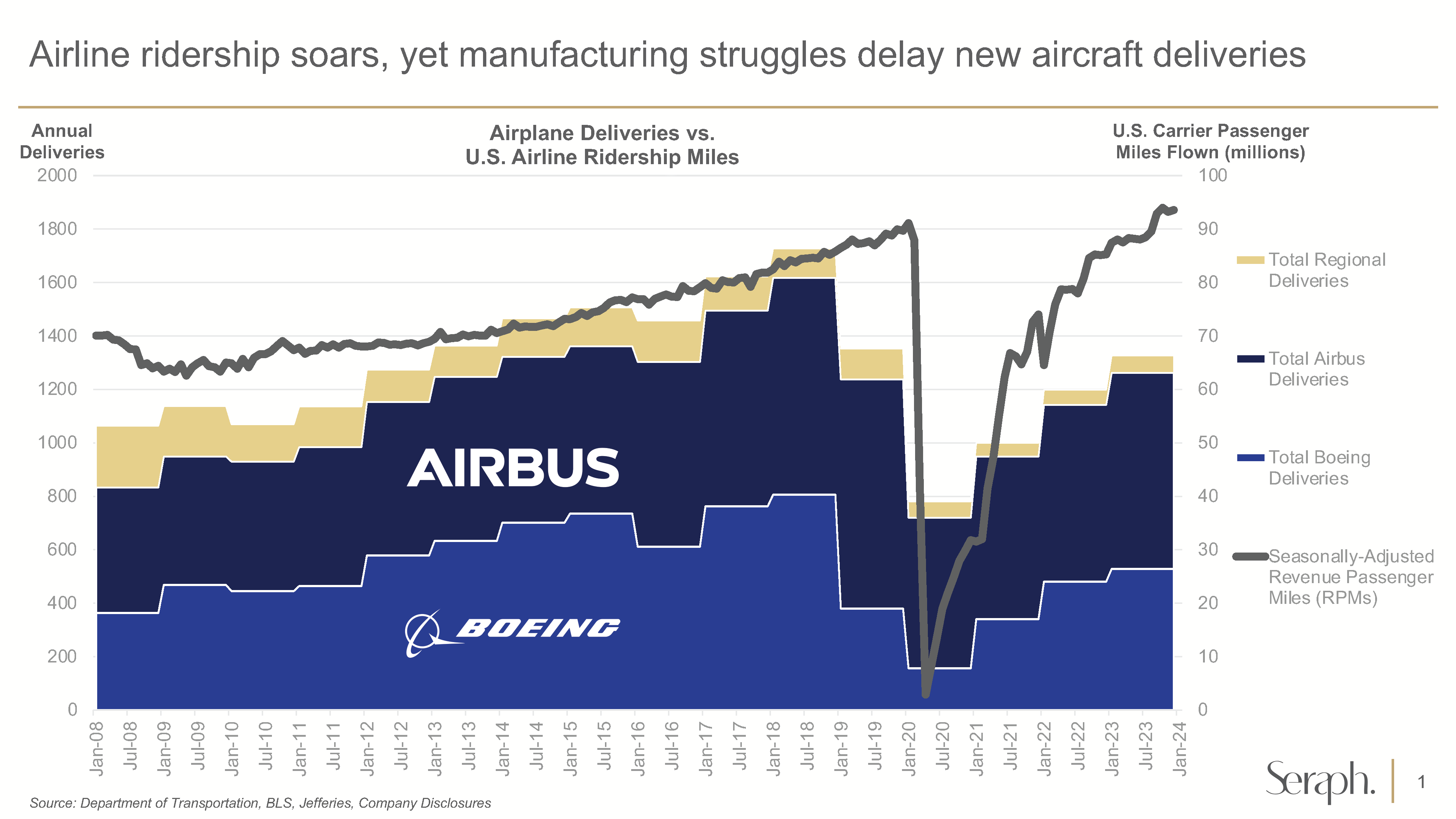

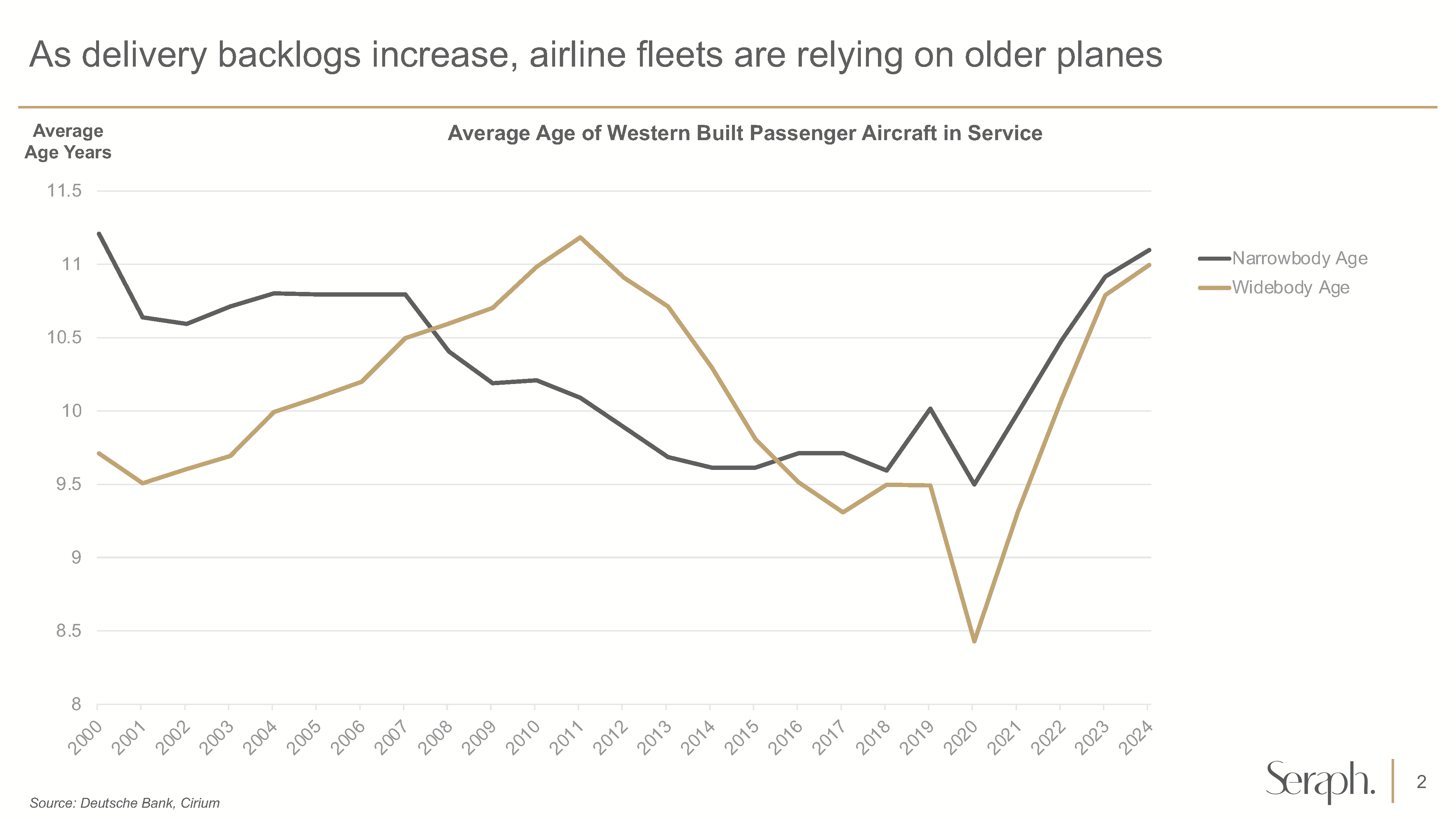

The aerospace industry needs to accelerate. We’re not taking off quick enough. The industry has endured substantial pain and disruptions nobody really expected. From 2019 onward, the industry was hit hard, and COVID drove it deeper. But now it’s 2024. Stagnation can’t be the new normal. Airline travel hit record highs in November and has stayed strong. Customers are begging for planes. We’ve seen a lot of this same pain in the automotive industry, but it’s turning a corner, and it’s now time for aerospace to do the same.

Here are 6 key areas in need of change:

Inventory Is Building Up and Straining cash-strapped balance sheets. Every CFO knows it. Every analyst asks about it. That’s what happens when you go from 6-7 turns a year to 2-3. Yes, the market conditions are hard and the FAA investigations aren’t helping. It might feel like you’ve done everything possible… I hate to burst your bubble but on a few recent aerospace assessments, there wasn’t even a plan for every part. Many companies haven’t changed their buying habits or regularly adapted their planning parameters, leading to value building up in warehouses and draining bank accounts. This isn’t bad news, it means you have the chance to keep improving. Manufacturing is not a by-the-seat-of-your-pants type job; consistency is crucial. Planning and material flow is no exception.

The Discipline Dilemma: When fatigue sets in, discipline is the first casualty. As people burn out, discipline is lost. The exception can’t become the rule. Ad hoc solutions lead to ad hoc results. Without a daily operating cadence, there is no foundation for continuous improvement. This has been further eroded by the loss of the knowledge of what good looks like.

The Talent Exodus: The frontline managers create the value, but we’ve left them unequipped. The industry has faced a significant loss of talent and exodus of skilled people with valuable experience. Frontline leaders, critical to keeping operations running and meeting the increasing ramp-up, were forged in crisis but haven’t been adequately invested in or developed. They’ve gotten used to firefighting, not operating with consistency and following established systems.

HR’s Strategic Focus: HR needs to get back to developing talent instead of just controlling costs. This type of mindset rarely works in purchasing and certainly doesn’t work with human resources. HR teams must focus on bringing in the right talent and having systems in place to support operations, quality, and logistics teams. Ensure that people are trained and that skills are being developed and retained within the organization. Strong frontline leaders and a robust management system are critical, especially during ramp-ups. However your company is structured, executives and leaders should empower human resources to acquire and develop the talent needed for stable performance.

Leaders are Data-Rich, Knowledge-Poor: So many dashboards and charts, but not enough clear direction, and more importantly, actions tying back to closing gaps in performance. I know AI is the hot topic right now, and it has a place. But rolling out AI without a steady state won’t do you any good. Change management is challenging, and the often neglected majority of the work required to get value out of a new tool In my 35 years of manufacturing, I haven’t found any silver bullets (for no shortage of trying). Hoping AI will magically turn data into profits and solve problems is unrealistic. If you don’t believe me, go call one of your exec friends that rolled out a big AI program and ask them if it worked as expected. My guess is that they faced a lot of challenges.

Back to Basics: Let’s be brutally honest – we’ve lost sight of the fundamentals. One of the fastest ways to amp things up is low-tech, daily consistency. Start with the simplest tools, narrow the focus, increase the intensity, and start banking wins that get people excited to come in and win the day. Establish a daily management cadence that makes sense.

Conclusion: All is not lost. The aerospace industry has the potential to soar, but it requires a relentless focus on the fundamentals. By reinvesting in talent, embracing discipline, optimizing inventory management, and leveraging data effectively, aerospace companies can emerge stronger and more resilient. Continuous improvement isn’t sexy, but it is what delivers results that shareholders love and a workplace people love. It’s time to drive performance to new heights.

About Seraph

Thanks to our team of specialized operational consultants, Seraph can work alongside manufacturing operations and act as a support structure to add value from day one. Our advisors are former management at many suppliers and OEMs and are experts in production and operational efficiency. Contact us to schedule a discovery call, or see our case studies for more information.

Seraph is a global operations and strategy consulting firm, that leads value chain improvements, restructurings, and turnarounds. We unite the disparate roles in operationally intensive businesses to create efficient operations, bridging the divide from concept to production. High-level decision-makers in manufacturing and industrial organizations rely on us to solve complex issues and launch initiatives that ensure success and sustainable change.

Author

Jack Caccioppo

Managing Director