The medical device sector is expected to exceed $800 billion in annual revenue by the end of the decade. Yet, recent disruptions – such as heightened geopolitical tensions, tariffs, and supply chain volatility – have created unprecedented inventory and logistics challenges. Medical device manufacturers now face mounting pressure to balance operational excellence with cost control and patient care.

Given that supply chain and inventory management are the second largest expenditure for medical device manufacturers, the stakes are high. Optimizing inventory isn’t just about cost savings – it’s about safeguarding healthcare outcomes by ensuring critical medical devices are delivered on time, every time.

Emerging Challenges in Global Inventory Management

While traditional pain points like poor supply chain visibility and system disintegration remain prevalent, recent developments have exacerbated inventory inefficiencies:

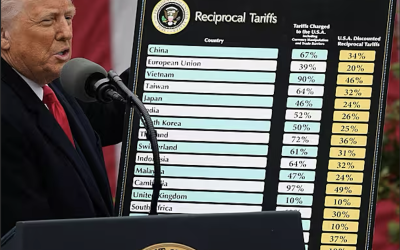

Geopolitical Instability and Tariffs

Global uncertainty, shifting trade policies, and punitive tariffs have disrupted material sourcing and logistics routes. Manufacturers reliant on specific regions (e.g., Asia-Pacific) for key components now face added layers of risk, including volatile costs and sudden supply interruptions.

Regulatory Complexity

The growing regulatory burden, such as compliance with evolving FDA, EU MDR, and ISO 13485:2016 standards, has added strain to already overextended operations. Misalignment between inventory strategies and quality systems (QMS) can result in costly non-conformances and even product recalls.

Supply Chain Capacity Constraints

The post-pandemic landscape continues to see bottlenecks across freight networks and raw material supply chains, forcing manufacturers to hold more buffer inventory than optimal, driving up carrying costs.

The Evolving Role of Seraph in Inventory Optimization

To address these evolving challenges, Seraph has expanded its service offerings for medical device manufacturers, focusing on supply chain resilience and inventory efficiency. Leveraging our hands-on, data-driven approach, Seraph specializes in operational and supply chain transformations that stabilize operations, unlock trapped working capital, and ensure regulatory compliance.

Here’s how Seraph can address the latest inventory and supply chain issues:

Integrated Digital Systems & Production Data Collection

Seraph’s operational software enhances real-time production transparency, enabling early detection of inventory shortfalls or inefficiencies. Combined with QR-coded material traceability linked to ERP systems, manufacturers can drastically improve forecasting accuracy and responsiveness.

Supply Chain & Logistics Transformation

Our logistics experts lead targeted initiatives to build supply chain resiliency, including supplier diversification, lean material flow improvements, SIOP processes, and regulatory-compliant traceability systems. These strategies help mitigate geopolitical risks while reducing waste and excess inventory.

Strategic Consolidation & Relocation

Seraph supports clients in reshoring or nearshoring production and consolidating supply networks to reduce dependency on volatile trade regions. Our structured approach ensures a seamless transition, including MDR readiness, process validation, and supplier qualification.

Assessment & Appraisal for Risk Mitigation

Through our comprehensive 170+ point assessment process, Seraph identifies operational gaps in inventory and supply chain systems, benchmarking against FDA, EU MDR, and ISO standards. This method uncovers potential regulatory risks and capacity issues before they affect production.

Updated Best Practices for Inventory Management

In light of today’s environment, here are refined strategies for medical device manufacturers:

- Build Multi-Tier Supply Chain Visibility

Go beyond Tier 1 suppliers. By enhancing end-to-end transparency – including sub-tier suppliers – manufacturers can better anticipate risks from upstream disruptions, tariffs, or raw material shortages.

- Prioritize Agile Inventory Strategies

Adopt flexible inventory models such as postponement, decentralized stocking for critical SKUs, and hybrid JIT solutions. This will allow manufacturers to respond swiftly to demand fluctuations or regional disruptions.

- Strengthen Internal Collaboration

Close the gap between Quality, Operations, and Supply Chain teams. Unified decision-making helps ensure that inventory strategies not only optimize costs but also uphold patient safety and regulatory standards.

- Embed Continuous Improvement Culture

Equip teams with lean methodologies and standard work practices to improve material flow, reduce cycle times, and consistently meet KPIs tied to inventory performance.

How Seraph Delivers Sustainable Value

Seraph’s four-phase methodology – Understand, Stabilize, Sustain, and Transition – has been instrumental in helping medical device clients achieve supply chain excellence and operational resilience. With an average ROI of over 300% and a payback period of less than six months, Seraph delivers both rapid stabilization and long-term improvements.

Whether your organization is navigating a post-merger integration, responding to increased regulatory scrutiny, or countering tariff-driven cost surges, Seraph’s MedTech expertise ensures a tailored approach to solve your most complex inventory and supply chain challenges.

Contact us today to schedule a discovery call, or see our case studies for more information.