Project Management Consulting Services

Launching new initiatives requires coordination across all business units. Successful launches require equal knowledge about which actions to take and which actions to avoid.

Navigating Complexity to Achieve Growth

A company’s ability to deliver large strategic initiatives determines its growth trajectory. Launching new products or entering new markets requires coordination at scale. However, the complexity of such projects often leads to unforeseen hurdles that must be understood in the context of company culture, management practices, fluctuating supply chains, and a dynamic market.

Effectively delivering on projects and programs designed to elevate an enterprise means knowing what to do when inevitable derailments occur. Transformational strategies developed through project management consulting only become meaningful when translated into real results.

• • • • • • • • • •

Our Approach to Project Management

• • • • • • • • • •

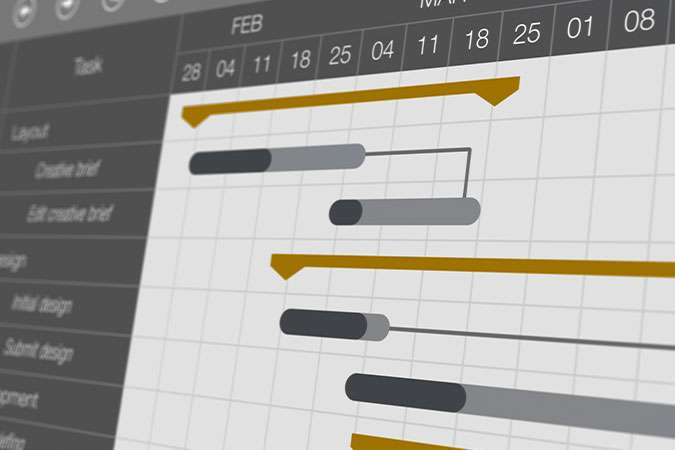

Seraph’s approach to project management is based on rapid learning and modeling of both product and process, delivering a program that moves quickly through a series of steps that activate thinking and help gain understanding. Traditional workshops take weeks and sometimes months to accomplish this; Seraph, using tools like 3P, which condenses this process into as little as 4-5 days.

Our projects have resulted in as much as 20% reduction in manufacturing costs and 40% reduction in capital costs. We operate cross-functional teams that evaluate and converge upon optimum solutions at the assembly, sub-assembly, component, and manufacturing process levels. Our deep manufacturing leadership experience bridges costly gaps in communication, helping your organization achieve smooth handoffs as the product moves toward industrialization.

Why Choose Seraph for Project Management Consulting Services

Successful project management requires an experienced team executing a clearly defined strategy, supported by all necessary resources. Regular, transparent communication and real-time data monitoring are required to stay on track and move forward. Seraph brings experienced leadership that keeps a diverse set of stakeholders engaged and on plan.

Our subject matter specialists have experience as program managers, continuous improvement managers, and global quality leads. We are comfortable working as an extension of your organization to ensure your most ambitious projects are managed effectively and efficiently. Count on Seraph’s clear communication and tactical management to keep you informed and on track.

Case Studies

Find out more about the companies who trusted Seraph to write their success stories.

Case Study: Global Mobility Technology Company Improved Standards After VDA Audit, Anticipating a Successful Re-Audit and New Business Opportunities

INDUSTRY: Automotive and Electronics Manufacturing SERVICES: Program Management. Crisis Management. Product Launches. Situation. Seraph was contacted two weeks before a VDA audit that the Client knew they were not prepared for. With such a short timeframe, the Client...

• • • • • • • • • •

Project Management Impact Numbers

• • • • • • • • • •

150+

projects successfully managed

18%

average reduction in project costs against original projections

80%

of project timelines are reduced in duration from Seraph’s involvement

• • • • • • • • • •

Seraph’s Consulting Experts

• • • • • • • • • •

Seraph’s leadership team is made up of former COOs, plant managers, and VPs of Operations in some of the world’s largest manufacturers and suppliers. Our wealth of expertise comes from years of experience in identifying the root causes of problems and creating actionable plans to restore prompt manufacturing operations and stakeholder confidence.

• • • • • • • • • • • • • •

INSIGHTS

• • • • • • • • • • • • • •

OUR TAKE ON MANUFACTURING

Interviews, videos, case studies, and more.

Effective Inventory Management Strategies for Medical Device Manufacturers

The medical device sector is expected to exceed $800 billion in annual revenue by the end of the decade. Yet, recent disruptions - such as heightened geopolitical tensions, tariffs, and supply chain volatility - have created unprecedented inventory and logistics...

IN THE NEWS

The latest from various industry sources.

Global Tariff Impact: Breaking Down Potential Impact and Responses From Europe

Ambrose Conroy joined RTE to discuss the Global Tariff Impact and how it may potentially impact Europe and looking into the European response

Learn How Seraph Can Help Your Business