To navigate the current global climate, it is critical for businesses to recognize and prepare for escalating conflicts around the world. While traditional wars between nation-states, such as Russia’s invasion of Ukraine, are increasing, non-traditional war zones are also becoming more frequent and widespread, leading to a complex geopolitical landscape. As a result, companies that are strategically positioned to take advantage of these conflicts will benefit commercially, while those that are unprepared will become victims of the resulting chaos. It is essential for companies to recognize the potential opportunities and risks associated with this changing global climate, and to adapt their strategies accordingly to ensure their success in the long run.

It is crucial to comprehend that these conflicts are expected to escalate in the years to come, especially in regions with typically weak or ineffective governance, such as Africa, Southeast Asia, and Latin America. The competition for scarce resources in these areas has the potential to generate rivalries and tensions between nations that have not been seen in many decades. The rising threat posed by China, coupled with its increasingly outward aggressive posture, highlights the possibility that these conflicts could become increasingly kinetic and potentially have global consequences.

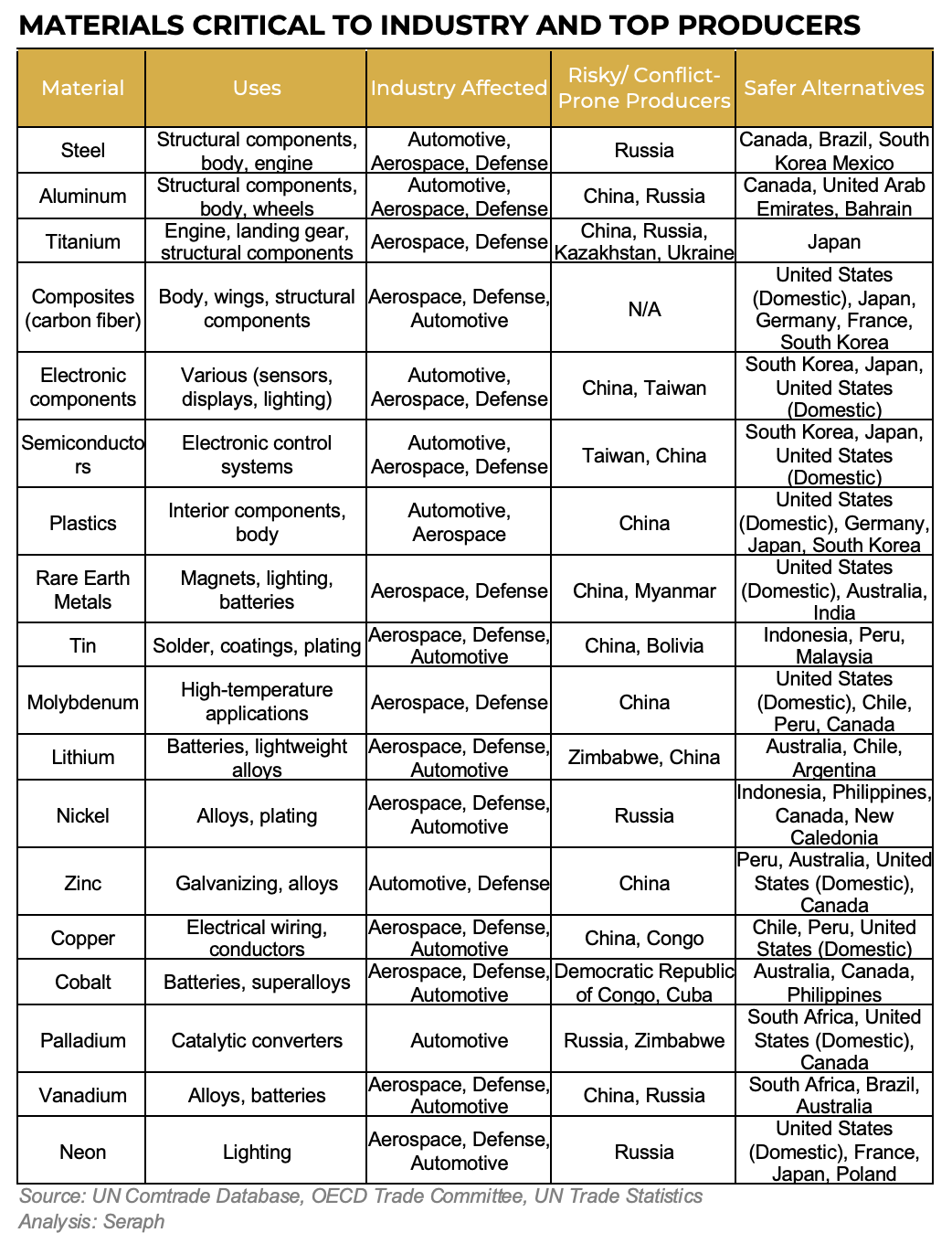

The impact of rising tensions between the USA and China, along with the potential for sanctions, could have significant effects on materials that are integrated into the automotive, aerospace, and defense industries. As conflicts continue to escalate, companies must prepare for potential disruptions to their supply chains and sourcing, especially in regions with weak or ineffective governance. The rising threat posed by China and other emerging conflict zones highlights the importance of companies strategically positioning themselves to take advantage of opportunities and mitigate risks.

The re-emergence of great power rivalry, a phenomenon not witnessed since the collapse of the USSR, looms ominously over the geopolitical landscape. The potential for this rivalry to ignite conflicts, not only in the South China Sea but also around the world, as countries compete for valuable resources, is a concerning reality. The Democratic Republic of Congo (DRC) is a stark example of this scenario as it suffers from a volatile mix of violence and political instability, while being home to highly coveted mineral resources that are essential to the high-tech industry and critical to the national security priorities of multiple nations. There are many other mineral-rich countries critical to the supply chain of the automotive, defense, and aerospace industries that also face instability threatening their supply chains.

The rising tensions between global powers necessitate that businesses must prepare to adapt and position themselves accordingly to take advantage of emerging opportunities. Neglecting to do so could result in missed opportunities and potential setbacks. Therefore, it is essential for businesses to prioritize resiliency in their supply chains by investing in the necessary resources, systems, and talent to navigate and take advantage of the shifting global landscape.

IMPACT OF RISING USA-CHINA TENSIONS AND POTENTIAL FOR SANCTIONS

As we are all aware, the relationship between the United States and China has been gradually deteriorating due to the escalating geopolitical rivalry, trade imbalances, and human rights violations, along with mounting concerns over China’s technological advancements that threaten to undermine US global supremacy. Recent events have only served to exacerbate these tensions to unprecedented levels, most notably the discovery and subsequent downing of a Chinese spy balloon that violated US airspace and collected intelligence on sensitive military installations.

In response to these provocative actions, President Biden has implemented new sanctions against six Chinese firms that support China’s military. Furthermore, recent trade restrictions targeting China’s high-tech and semiconductor industries aim to slow China’s ability to compete in the technology sector, without which China’s ability to compete economically and militarily would be neutered. This highlights the potential consequences of escalating tensions between the two nations, including the worst-case scenario of a Chinese invasion of Taiwan and a possible US-led response.

CURRENT STATE OF USA-CHINA TRADE

The economic relationship between the United States and China is unparalleled in size and complexity, with both nations still heavily reliant on each other despite recent decoupling in areas such as high tech. In 2022, the trade imbalance between the two countries was $383 billion in China’s favor, with the U.S. importing $537 billion and exporting $154 billion. This staggering imbalance underscores the depth of interdependence between the two economies, particularly in terms of consumer and commercial goods, medical supplies, pharmaceuticals, and the intermediate processing of raw materials. Any imposition of sanctions on China poses a complex challenge given the extensive interdependence of the U.S. and its allies with the Chinese economy. Each economy relies on the other for different items as shown in the graphics at the end. For example, although China may not directly be a producer and exporter of raw materials to the United States, it plays a critical role as an intermediary processor for many materials, transforming them from their raw stage into inputs suitable for higher-level manufacturing. For instance, iron ore needs to be processed into pig iron to produce various types of steel. China is by far the world’s largest producer of pig iron and plays a critical role in supporting the world’s steel-based industries.

RUSSIA SANCTIONS PLAYBOOK

Sanctions used to be viewed as a less-than-serious tool in the international community, but the devastating economic impact of the financial sanctions leveled against Russia by the United States and Europe since the invasion of Ukraine has completely changed that perception.

Russia’s invasion of Ukraine led to an unprecedented escalation of economic statecraft, with coordinated Western sanctions severely limiting Russia’s access to advanced technologies and isolating the country. The United States chose to coordinate with traditional allies and partners, a coalition of more than 30 democracies accounting for more than half of global economic output, to impose severe restrictions on trade with Russia.

The coordinated nature of the sanctions magnified their impact, making it more difficult for Russia to evade them. This raises questions about whether coalition policymakers can remain united in response to other pressing challenges, such as the growing power of China.

The question arises: Could we impose comparable sanctions on China in the event of a hypothetical invasion of Taiwan? While the answer is likely yes, it is important to note that the costs would be significantly higher for all parties involved due to the increased complexity and extensive entanglement of the Chinese economy with the United States and its allies.

THE WORST CASE: CHINESE BLOCKADE OR INVASION OF TAIWAN

The global economy could be on the brink of a catastrophic hit estimated at a minimum of $2.5 trillion per year if China invades or blockades Taiwan. The impact would be extensive, affecting global trade and investment on an unprecedented scale, with the repercussions, felt immediately and difficult to reverse. Even if the conflict does not escalate to involve other combatants like the United States and its allies, the disruptions would leave few countries untouched.

The most significant impact would be on Taiwan, where a blockade scenario would result in a halt to trade, particularly in semiconductors. The world relies heavily on Taiwan for advanced logic chips, with Taiwan producing 92% of these chips. Many industries depend on equipment containing Taiwanese chips, including electronics, automotive, and computing, and they could be forced to forgo as much as $1.6 trillion in revenue annually in the event of a blockade

The United States and Europe would also suffer significant economic impacts, although the European Union, which exports more to China, would be hit harder than the US, particularly in critical goods such as pharmaceuticals and chemicals. While both the US and Europe rely heavily on Chinese imports in various industries, the US economy is not as heavily reliant on exporting to China, which would spare it further damage in an escalating economic war.

Disruptions in Chinese imports would cause noticeable shortages, rising prices, and discomfort for consumers and producers in importing countries. However, China’s export-focused economy, with over 50% of its exports going to the US and US allies, is highly susceptible to Russian-style sanctions. Even if sanctions or military escalation do not occur between the US and China, disruptions to global trade finance would significantly impact trade between China and the rest of the world.

China would be the most open to damage in this scenario because its economy is heavily reliant on foreign imports to fuel its economic machine while also relying on its exports to the world to generate income. Also, losing access to Taiwanese semiconductors would be a severe blow to China’s manufacturing sector and the overall economy. Investors would reduce their exposure to possible financial sanctions and broader economic risks, leading to a further decline in China’s economic activity.

IMPACT OF OTHER RISING CONFLICTS AROUND THE GLOBE

The global supply chain is currently experiencing multiple bottlenecks, including shortages of tin, molybdenum, lithium, oil and gas, lumber, nickel, zinc, and wheat. These shortages have the potential to cause significant downstream impacts on businesses and consumers and are expected to persist. These scarcities could lead to further instability. Example conflicts impacting global supply chains:

Afghanistan – Speculation that China will seek to dominate Afghanistan’s mineral resources, including lithium, after the U.S. withdrawal in 2021. Resources at risk: Lithium for electric vehicles and clean energy storage systems, copper, nickel, cobalt, and rare earth elements.

The Taliban are sitting on $1 trillion worth of minerals the world desperately needs | CNN Business

China – U.S. export controls on cutting-edge chips, chip design software, chip manufacturing equipment, and US-built components of manufacturing equipment, as well as prohibiting U.S. citizens from working in Chinese chip firms. Resources at risk: Semiconductors and chips.

Trade War Impact on Automotive Industry

Myanmar – Due to the regime’s foreign currency controls and the restricted supply of fuel, becoming increasingly difficult to buy gasoline and diesel resulting in businesses halting operations unless availability improves. Resources at risk: OEM components due to fuel shortages

Motor vehicle factories in Myanmar under threat of closure | Thai PBS World

Pakistan – Auto assemblers in Pakistan will likely witness a delay in the import of CKD kits in the near term after SBP’s downward revision of the import transaction approval limit to $100,000 from $500,000. Resources at risk: CKD Kits; imports disruption

Auto assemblers in Pakistan likely witness delay in import of CKD kits – Mettis Global Link

Russia – Russia’s invasion of Ukraine and the ensuing sanctions have significantly affected the availability of raw materials and the prices of those left on the global markets.

Resources at risk: oil, gas, agricultural products, aluminum, nickel, palladium, vanadium, potash (fertilizer input), neon gas The supply of critical raw materials endangered by Russia’s war on Ukraine

Ukraine – Much of the country’s manufacturing and mining capabilities have been destroyed or impeded due to Russia’s invasion. Resources at risk: wire harnesses, neon, agricultural products

Exclusive: Russia’s attack on Ukraine halts half of the world’s neon output for chips | Reuters

Yemen – Ongoing war in Yemen threatens the millions of shipping containers and barrels of oil that pass through the Bab el-Mandeb off Yemen’s coast every day. Increased threats could cause insurance costs to rise and ships to take alternative, longer routes hence increasing. costs. Resources at risk: security of vital strategic sea route

Yemen war risk could strangle strategic sea trade routes | Reuters

In addition, other areas to consider include high-risk zones around the world, such as Beirut, Iraq, Israel, Libya, Mogadishu, Syria, Somalia, Bangladesh, Brazil, Colombia, Haiti, Mexico, and multiple countries in Africa. These regions present significant opportunities for growth in our target area.

IDENTIFYING KEY MATERIAL INPUTS AND ALTERNATIVE SOURCES

The global supply chain has made it possible for manufacturers to source materials from different parts of the world. As global supply chains have become increasingly interconnected, the dependence of businesses on certain key materials has grown. However, it has also made companies vulnerable to disruptions that may arise from political, economic, or environmental factors. This vulnerability is particularly evident in the automotive, defense, and aerospace industries, which depend on specific raw materials for their products. The chart below identifies many of these key materials, their common usage, and the top producers/exporters of these materials to the United States.

As is evident within the data, many of the critical inputs American manufacturers need to thrive are reliant on regimes historically unfriendly to the United States or regions that are experiencing or have the potential to become geopolitical hotspots. By understanding the vulnerabilities inherent in some of these materials along with potential alternatives, companies in these industries can reduce their risks and strengthen their supply chain resilience by potentially sourcing critical materials from friendlier and more stable countries.

Take the example of China, a major producer of many of the key materials identified in the chart. With rising tensions between China and the USA that have been described earlier, there is a growing risk that businesses may face significant disruptions to their supply chains due to the ratcheting up of tensions leading to potential sanctions and even war. This could result in increased costs, delayed production, and even product shortages.

WHAT BUSINESS LEADERS CAN DO

Given the potential implications of escalating tensions between China and Taiwan, US businesses should consider taking a number of proactive steps to prepare. The risks of not doing so are too great to ignore, and businesses that fail to take action may find themselves facing significant disruptions and increased costs in the years to come.

- Assess supply chains to identify any areas where they are heavily reliant on areas of rising tension and potential conflict.

- Companies may want to look for alternative suppliers, stockpile critical components, or explore opportunities to reshore production in order to reduce their exposure to potential disruptions.

- Stay informed about the latest developments in the region by monitoring geopolitical risks and engaging with industry associations or government agencies to stay up-to-date on potential changes to trade policy or regulations.

- Develop contingency plans in case of disruption, such as diversifying their supplier base, increasing inventory levels, or exploring alternative markets.