INDUSTRY: Automotive Manufacturing

SERVICES: Assessment. Production. Operations. Staffing. Engineering and Maintenance. Quality.

Situation.

A tier one automotive supplier was shutting down their customer due to low JPH (Jobs per Hour) performance caused by downtime, scrap-rework, and performance efficiency. Seraph’s assessment uncovered specific areas to target to improve JPH and reduce customer downtime at the JIS (Just in Sequence) plant.

ACTIONS.

3 key work packages:

WORK PACKAGE 1 |

Recovery Management |

Objective: Improve production output to required RPH 45 to appropriate targeted headcount. Deliverables: •Managed the turnaround project to a sustainable operating cadence. •Supported plant manager and local leadership team. •Evaluated organization, executed structural recommendations and competency evaluations. |

WORK PACKAGE 2 |

Production Readiness |

Objective: Reduced downtime occurring at the customer by increasing JPH and performance efficiency. Deliverables: •Trained frontline leadership. •Increased production to requirement while delivering desired quality. •Deployed daily management system to drive increase in JPH from 27 to 45. |

WORK PACKAGE 3 |

Engineering / Maintenance and Quality |

Objective: Established an efficient equipment maintenance and contingency system, minimized downtime, reduced scrap and first pass yield to target levels. Deliverables: •Developed contingency plans for all assembly processes. •Developed a review process to improve PM (Preventative Maintenance) activities. •Reduced rework and scrap. •Developed a robust process for spare parts management. |

Key Improvements.

- Identified and supported improvements in management shortcomings, gaps and competency issues.

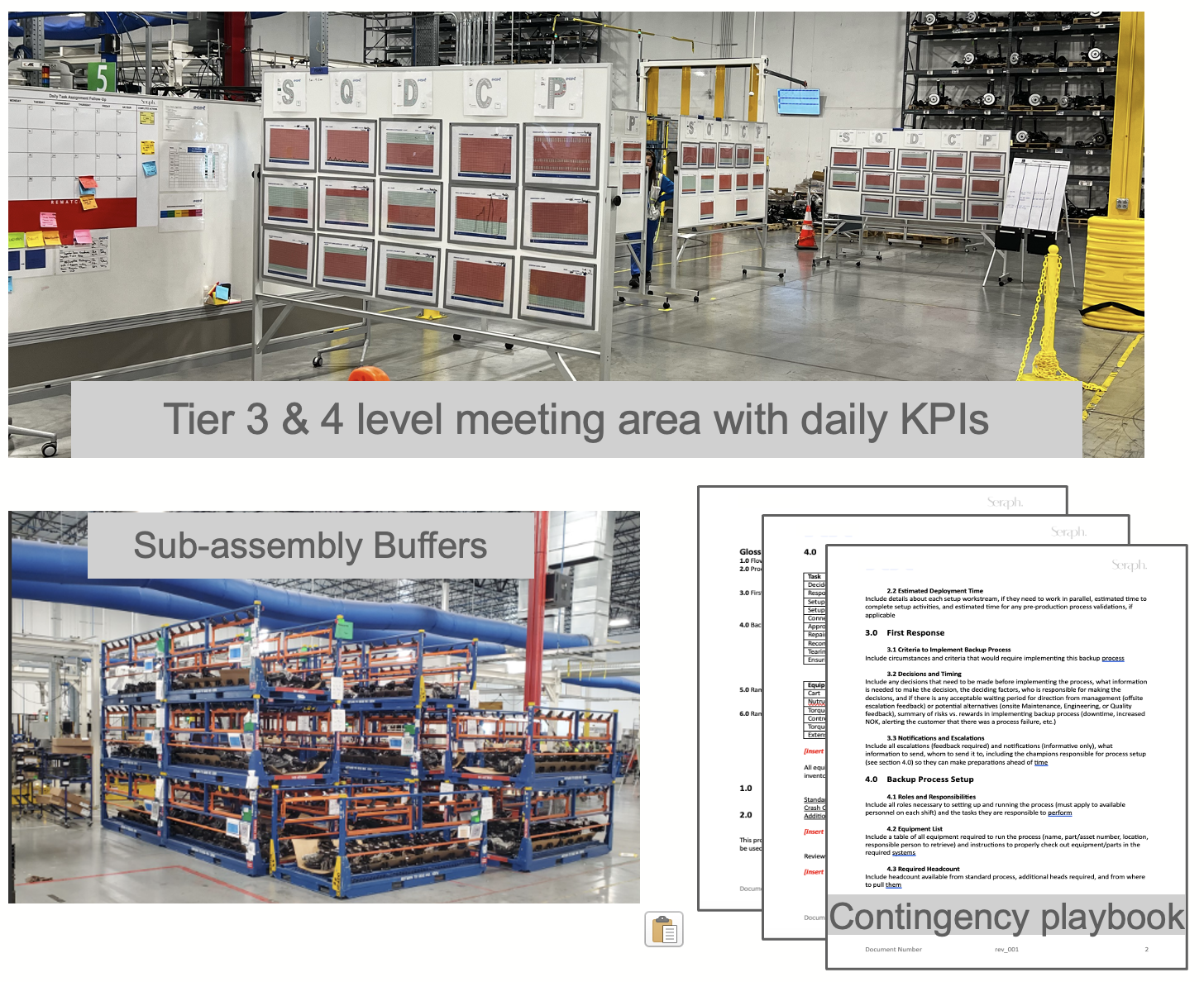

- Defined KPIs that drove operations toward the JPH and quality targets, making these visible on the floor and reviewed daily in tiered meetings.

- Reduced headcount by identifying ways to reduce over budget resources, while defining needed RTR (Required To Run) to reach required JPH of 45 and then 52.

- Revised work instructions to reflect best methods to achieve targeted JPH.

- Transitioned subassemblies away from building to sequenced call-offs, to building to a managed buffer feeding the main production line.

- Updated and implemented standard escalation process related to a JIS operation.

- Contingency playbook created which included an implementation project action plan and timeline for each station and process.

- Used machine data to create paretosto identify top issues causing scrap and rework to drive permanent improvements for elimination of top issues.

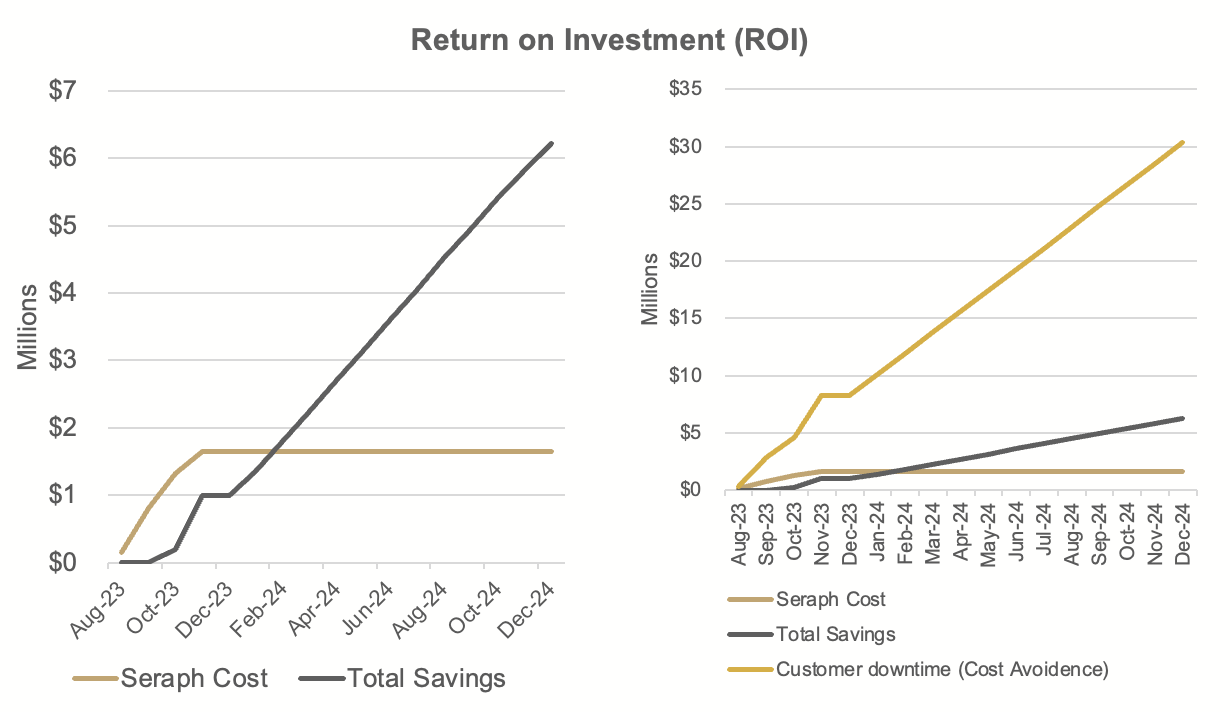

RESULTS.

- Seraph reduced target line headcount by 3.8% and overall headcount by 6.2%.

- JPH increased by 44.4%, maximim JPH per hour increased by 43.9%*.

- *JPH numbers were not higher due to limited number of call offs.

- Plant downtime decreased by 63%.

- Customer average vehicles lost decreased by 100% when comparing the 4 weeks before Seraph’s arrival to the last 4 weeks of the project.