The State of Cashflow in the Automotive Supply-Base

Recent OESA analysis confirmed many of the concerns expressed by OEM, Tier 1, and industry experts. The outlook is bleak. OESA’s Q2 2020 report shows the Supplier Barometer IndexTM(SBI) at 15, which is the lowest level ever recorded in the history of the metric.

Suppliers are coming under the watchful eye of customers due to financial distress. OESA reported a 600% increase of distressed suppliers in Q2 2020. Several factors have come together to increase the number of distressed suppliers. To meet increased localization requirements in the USMCA, suppliers have undertaken arduous supply chain modifications . Next, with the ongoing impact and concerns from the COVID-19 pandemic, more suppliers are coming under the watchful eye of customers due to financial distress.

OESA reported a 600% increase of distressed suppliers in Q2 2020 with even more that are considered borderline. Finally, OEMs are planning for significant changes in overall volumes worldwide as the supply chain comes back to life and markets struggle to reopen.

As the automotive industry restarts after and extended shutdown due to COVID-19, operational challenges and increasing costs (demand volatility, supply chain disruptions, PPE cost increases, etc) will continue to strain the cashflow of suppliers. Action is required to mitigate the associated issues; a company’s failure to act can prove fatal.

A Proven Action Plan and Tools

Seraph has developed a robust, methodical process and highly effective tools which we have used to turn around numerous financially distressed companies. As a partner representing the operations discipline, Seraph has collaborated with major financial consulting companies to bring to bear a combined operations-finance perspective.

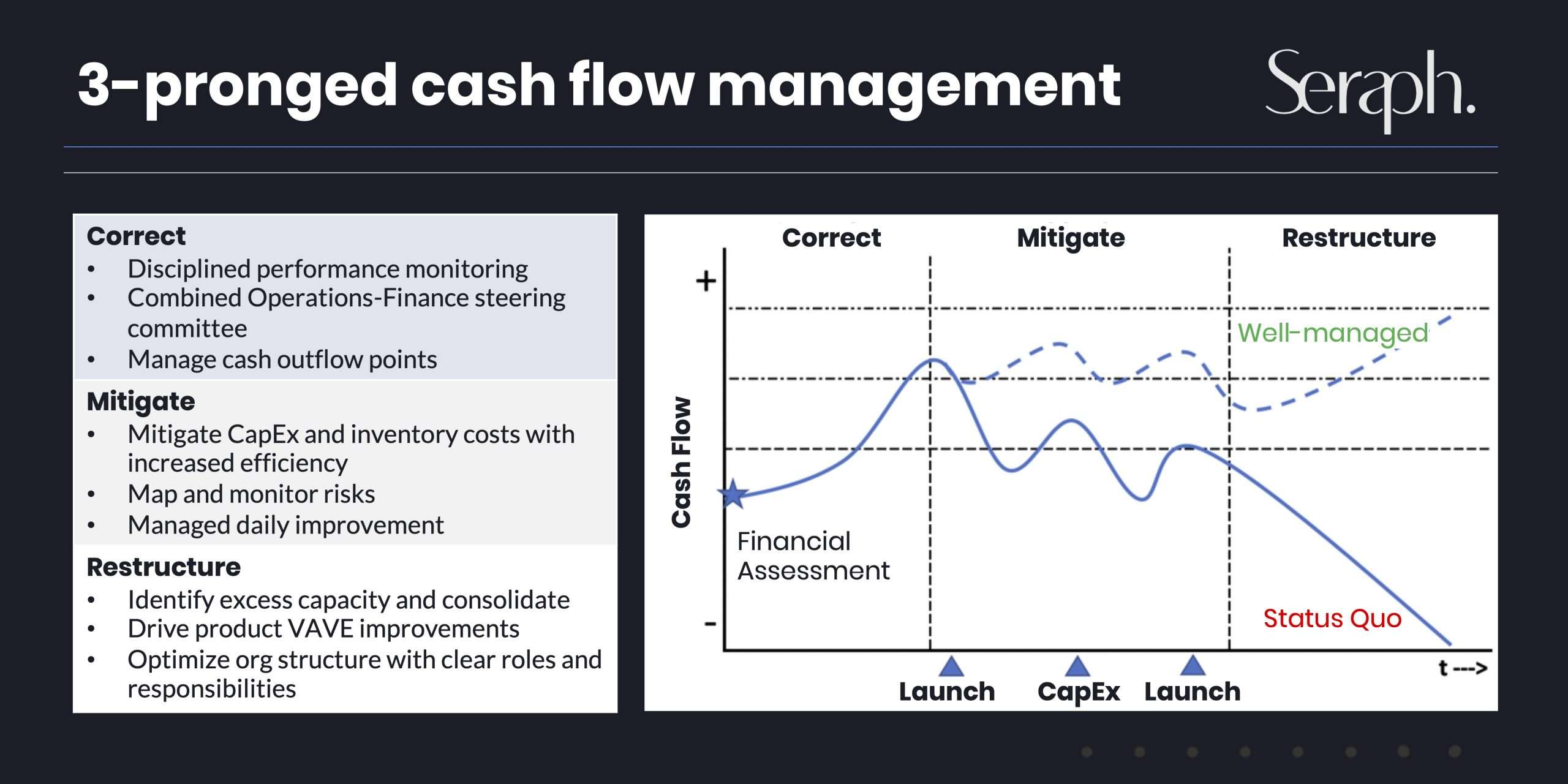

Correct

Cashflow correction may be be required to offset the high start up costs to regain positive cashflow immediately.

- Implement a disciplined approach to monitoring performance on a frequent and regular basis.

- Establish a steering team consisting of Operations and Finance membership.

- Rigorously manage the cash outflow points of the operation.

Mitigate & Improve

Mitigation of predictable risks or improvement of marginal situations may be necessary to preserve positive cash flow.

- Improve efficiency to eliminate the need for capital spending or increased inventory.

- Map and monitor potential future cashflow challenges and mitigate them with intensity.

- Implement or refine the process to manage improvement daily.

Restructure

Restructuring could be required to adapt to new market conditions.

- Complete a network capacity plan and identify opportunities to consolidate.

- Drive product VAVE improvements to reduce product and process cost.

- Evaluate and revise the organization structure for efficiency with clarity of roles and responsibilities.

Successfully addressing operational issues to improve cashflow is critical to survival as the automotive industry roars back to life

Action is Critical to Survival

Successfully addressing operational issues to improve cashflow is critical to a company’s survival as the automotive industry roars back to life. With our proven processes and tools, expert operational resources, and decades of experience, Seraph is the partner for your organization’s success during these critical times.

About Seraph:

Seraph’s team of operational experts and senior consultants intercede on our clients’ behalf to fix a crisis that is putting the business at immediate risk, turnaround a situation that is damaging the bottom line or restructuring to improve the balance sheet. Seraph has successfully delivered projects in the following regions: The Americas, Europe, China, and India. Seraph’s Industry Expertise Includes Aerospace, Automotive, Energy Infrastructure, Healthcare, and Medical Devices. Through our other operating companies, we are continually looking for distressed situations where we can put our expertise and capital to work to create value